Dear Mr./Mrs.

One of our good customers has complained, that they have a lot of problems with Bosch high pressure pumps on the MAN vehicles.

The new units 0445020023 / 0986437351 work well 6-12 months only and after that the diesel fuel mix with the engine oil. It is very complicated and expensive to claim these units at Bosch, so we are looking for alternative solutions.

We have a few questions regarding this issue:

- Is it a typical problem with the high pressure pumps?

- We received the following advice from our Bosch service: if you want to solve this problem, change to a high pressure pump that is lubricated with diesel fuel. For example: 0445020208 / 0986437350. What is your opinion regarding this advice?

- Do you know similar type failures with MAN, Bosch products? Do you have solutions for these problems? The description of these failures with the solutions would be very useful for us.

Thank you for your assistance in advance.

Best regards!

_______________________________________________________________________________________________________

Dear Mr./Mrs.

We have experience with that type of HP fuel pump. It is used on older MAN vehicles ( mostly D20-E3 engines).

This pump is lubricated with engine oil, and at the end of it’ s lifetime, it begins to mix engine oil with the pressurized fuel.

The fuel polluted with fuel flows further through high-pressure part of the fuel system and contaminates at the end the injectors and limits their functionality so the engine runs poor.

We can confirm that it is a way to short period for that kind of wear of the fuel pump, and in our opinion, the advice you got should be carefully analyzed and checked.

Longevity of brand new high pressure pumps of common-rail generation is regularly over 600 000-800 000 km, but rarely over 1000 000 km ( long distance transport ).

Our advice is to let the Laboratory from Bosch check the worn-out fuel pumps ( 0445020023/0986437351) in order to determine the wear pattern and its cause.

In our opinion, there are to possible reasons for premature wear of the pump:

- Inappropriate engine oil service interval – ( usually too long, maybe clogged engine oil filter – so the non-filtered oil flows through the over-pressure valve on the engine oil cooler modul, and wears all engine parts that it is lubricating with debris that are not filtered)

- Poor filtration capacity or limited filtration of particles larger than 3-5 microns ( due to lower diesel fuel quality which can contain – dirt and sediment, water, organic contaminants, or the usage of un-appropriate fine fuel filter)

So the advice you got to replace 0445020023/0986437351 with the 0445020208/0986437350 is feasible, but as a permanent solution questionable.

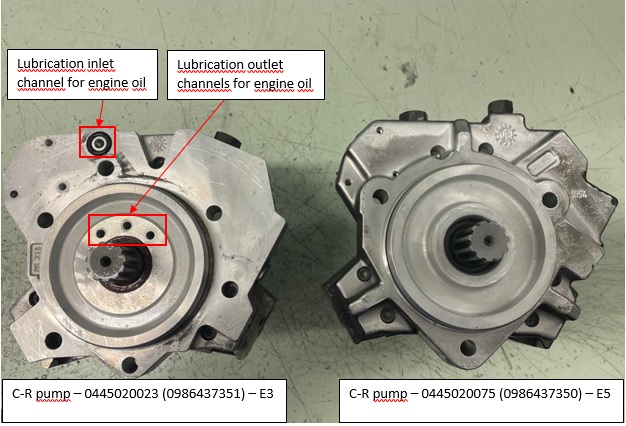

It has to be mentioned that these two types of fuel pumps are used on two different generations of vehicle ( 0445020023/0986437351- E3 and 0445020208/0986437350 - E4/E5).

The pressures are the same (1600 bar), but the 0445020208/0986437350 - E4/E5 has larger pump capacity (1100 ml/min, in comparison with 0445020023/0986437351 – 950 ml/min), what can be tolerated because of the fuel return.

The flange is similar, not the same, but it could be built on the engine with minor adjustments.

The fuel lines and electric cable for the M-Prop fuel valve can be connected without major adjustments, but the oil channel on the engine has to be blocked.

This solution is questionable because, firstly, the cause of the premature wear of the pumps has to be necessarily found.

If the engine oil service interval is to long ( or the oil is deteriorated), the whole engine will be worn-out prematurely, and, at the other side, if the fuel is of lower quality, the

fuel lubricated C-R pump 0445020208/0986437350 will wear-out prematurely as well. So the only advantage of that approach would be that the injectors wouldn´t be

contaminated with engine oil.

So there are two solutions that can be implemented:

- Shortening of engine oil service interval ( or better oil quality and it’s filtering),

- Adding an additional inline fine filter unit to the already existing one ( to improve the cumulative filtration properties of the KSC (Krafftstoffcenter – fuel fine filter modul).

But, this has to done only after checking the service history of the vehicle and analysis of the report from Bosch.

For the Laboratory purposes, oil and fuel samples would be very useful, additionally to the defect pump from the problematic vehicle.

I hope that these information will be helpful for finding alternative solutions for the problem you have in Asia.

If you do have more questions, don’t hesitate to contact us, we will certainly try to help.

Best regards,

BDC team